basic introduction

Industrial air conditioning—Air-cooled modular cold (hot) water unit uses air as the cold (heat) source, water as the cooling (heat) medium, and as the cold (heat) source-type integrated central air-conditioning equipment. The unit combines the advantages of high reliability, high efficiency and high automation. It is an air-conditioning host that is more convenient to use and more reliable.

Industrial air conditioning - basic configuration of air-cooled modular cold (hot) units

1, scroll compressor

2, plate heat exchanger

3, fan motor

4, coil

5. Electrical control components and other components.

Industrial air conditioning - main features of air-cooled modular cold (hot) units

1. The central air conditioning unit with air as the cold (heat) source and water as the cooling (heat) medium, that is, the condenser is a finned heat exchanger, and the evaporator is a heat exchanger for water and fluorine heat exchange application. Such as casing, shell tube and plate heat exchanger.

2. As an integrated equipment for both cold and heat sources, the air-cooled heat pump eliminates various auxiliary parts such as cooling towers, cooling water pumps, boilers and corresponding piping systems. The system structure is simple, the installation space is saved, maintenance and management are convenient, and energy is saved. Especially suitable for areas where water is scarce.

3, air-cooled heat pump unit is usually a lot of winter cold summer heat, neither heating boilers, nor heating network, or heating network heating time is short, unstable, requiring the annual air conditioning HVAC engineering design preferred Effectively supplemented.

4. The centralized and semi-centralized central air conditioning system consisting of fan unit, air conditioner box and other end devices has the advantages of flexible layout and various control modes.

Industrial air conditioning - air-cooled modular cold (hot) unit working principle

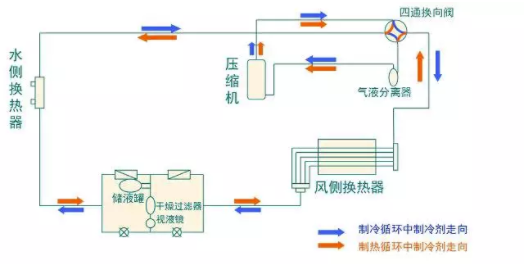

Cooling mode

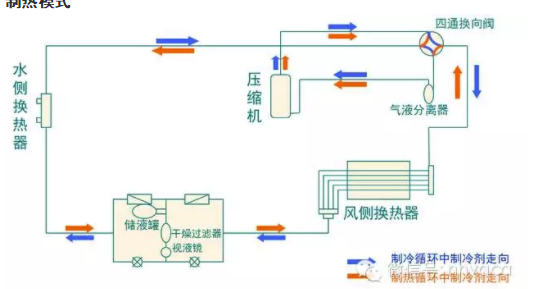

Heating mode

Cooling mode

Cooling mode: The refrigerant high-temperature gas discharged from the compressor is condensed into a liquid in the wind-side heat exchanger, throttled and depressurized by the throttling device, enters the water-side heat exchanger, absorbs heat and evaporates and returns to the compressor to complete a refrigeration. At the same time, the air conditioning water from the room is cooled and cooled by passing through the water side heat exchanger.

Heating mode

Heating mode: the high-temperature gas of the refrigerant discharged from the compressor is condensed into a liquid in the water-side heat exchanger, thawed and depressurized by the throttling device, enters the wind-side heat exchanger, absorbs the heat and evaporates, returns to the compressor, and completes a At the same time, the air conditioning water from the room is heated and heated by the water side heat exchanger.

Industrial air conditioners - selection of types and number of air-cooled modules for hot and cold water units

Generally speaking, when the nominal cooling capacity of a single unit is less than 116kw, the scroll compressor is mainly used; when the single unit capacity is 116kw~700kw, the screw machine is preferred; the single unit capacity is 700kw~1054kw. Screw machine or centrifuge is suitable; if the capacity of single machine is above 1785kw, the centrifuge should be selected.

The number of units should be determined according to the size of the project and the change in air conditioning load. From the perspective of flexible adjustment and energy saving, the number of units is better; from the perspective of equipment investment, floor space and maintenance management, the number of units is less. Generally choose 2 to 8 units. For modular machines with dual compressors, up to 8 units can be connected in parallel, that is, 1 unit and 7 units. For module units of 4 compressors, up to 4 units can be connected in parallel, that is, 1 unit and 3 units.

Industrial air conditioning - air cooling module hot and cold water unit installation precautions

1. The water filter must be installed, otherwise the unit board will be replaced by freezing and other failures.

2. Before the unit is running, it is necessary to test the impurities in the pipeline.

3. When snowing in winter, sweep off the snow on the coil to prevent damage to the compressor.

4. Unless the special requirements are met, the unit does not have a built-in water pump.

5. The water flow switch should be installed in the water outlet pipe close to the unit.

6. The filter of the unit needs to be cleaned regularly.

7. When installing multiple machines, ensure sufficient suction space to prevent short circuit.

8. There is a standard damping plastic pad on the base of the unit pallet to reduce the transmission of vibration and vibration.

9. When the cold and warm unit is installed on the ground, the unit should be at least 20cm away from the ground for drainage.