here are many factors that cause low-pressure failure of the freezer, which can be roughly divided into the following categories (from easy to difficult sequence): system leakage, system blockage, and insufficient heat exchange of the evaporator blockage. We only list some of the analysis today.

PS:

The "Reset button" on the pressure controller must be pressed after each fault point has been processed.

Fault 1: The system has leaked

There are leaks in the connecting pipe of the refrigeration system, such as welding problems, corrosion problems caused by the environment, fractures caused by mechanical vibrations, human factors, etc., causing low-voltage failures.

Approach

This kind of problem is relatively simple to handle. First, use a leak detection solution (soap water, or detergent) or a halogen leak detector. Generally, the leak point can be found. When the leak point is found, it is welded with welding equipment and the necessary vacuum treatment is performed. After the refrigerant is charged according to the specified amount of the factory, the equipment can resume normal operation.

Fault 2: System blockage

There are four reasons for the blockage of the refrigeration system:

a, blockage of debris;

b, ice block;

c, the solenoid valve is broken;

d. The expansion valve is damaged.

Jamming

Normal blockages occur at the inlet of the filter or expansion valve. Freezer manufacturers have installed "filters" in the refrigeration system to filter out impurities in the system. When the impurities in the piping of the refrigeration system accumulate to a certain extent, the filter will be clogged, affecting the throughput of the refrigerant in the system, and a low-voltage fault will occur in severe cases.

recognition methods

If the filter is clogged due to dirty system, it will only cause the cooling capacity of the device to drop, or even you will not be affected.

When the "filter" is slightly blocked, there is a temperature difference between the inlet and outlet of the "filter", and the inlet and outlet can be felt by hand.

In severe cases, condensation or frosting may occur in the filter. If the filter is exposed or frosted (the condensation does not occur when the machine is running), the filter is clogged.

Approach

Replace the same type of filter.

Ice block

Ice blockage is essentially the presence of moisture in the system piping. The moisture in the system runs with the refrigerant to the throttle valve (expansion valve) after throttling expansion, forming a low temperature and low pressure at the outlet of the throttle valve. When the evaporation temperature (throttle outlet temperature) is below the freezing point, the moisture in the refrigerant forms ice cubes here, which blocks the throttle valve (expansion valve) from forming a low pressure fault.

Ice plugs usually occur at the outlet of the throttle valve (expansion valve).

Approach

It is best to use a detachable filter with “calcium chloride” (a strong water-absorbing material), thoroughly filter the moisture in the system, and replace it with a disposable filter of the same model. Device.

Solenoid valve damage

Solenoid valve is an indispensable accessory in the refrigeration system. It has the function of protecting the safety of the system. (When the compressor stops working, the refrigerant is cut off, and the refrigerant is not allowed to continue to flow to the evaporator. If there is a large amount of refrigerant in the evaporator after the compressor stops, When the compressor is started again next time, it is easy to cause the compressor valve to catch liquid and damage the compressor). When the solenoid valve is damaged, the circulation of the refrigerant is blocked, resulting in a low voltage failure.

Identification: Solenoid valve is better judged, and the solenoid valve is broken in two cases:

1. The solenoid valve coil is burnt and the hair film cannot be opened. The solenoid valve coil can be measured by a multimeter to determine whether the solenoid valve is burnt;

2. The solenoid valve body itself is broken, causing the membrane inside the valve to not open. When there is a temperature difference between the inlet and outlet of the solenoid valve, it indicates that the solenoid valve is defective.

Expansion valve damage

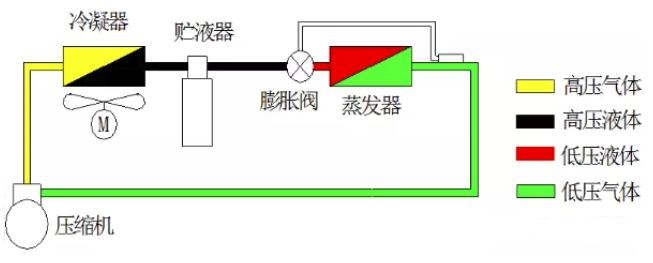

The expansion valve is one of the four major components of the refrigeration system and is an indispensable component. After the condensed low-temperature high-pressure refrigerant flows through the expansion valve, it is throttled by the expansion valve. At the outlet of the expansion valve, it expands and evaporates to form a low-temperature and low-pressure gas-liquid mixed refrigerant, thereby taking away heat in the system to form a refrigeration process.

The expansion valve has a mechanical expansion valve and an electronic expansion valve.

Mechanical expansion valves are affected by the environment during use. Some environments have corrosive gases that corrode the liquid, causing the expansion valve to corrode. Most of them are gas leaks in the temperature sensing package of the expansion valve (corrosion of the connecting tube connecting the temperature sensing package and the valve body).

Although the electronic expansion valve has the advantages of large temperature control range and high precision that the mechanical expansion valve cannot exceed, it has an independent control system, which also increases the failure rate invisibly.

Approach

In case of expansion valve damage, only replacement.

Fault 3: The heat exchange capacity of the evaporator is seriously insufficient

There are two reasons for the lack of heat exchange in the evaporator:

a, the evaporator water flow is insufficient

b. Blockage of foreign matter in the evaporator (or fouling on the surface of the evaporator tube in the evaporator, or crystallization causes insufficient heat exchange)

Insufficient water flow in the evaporator

The main factors causing this phenomenon are water pump failure or foreign matter entering the pump impeller, or air leakage in the pump inlet pipe (more difficult to check, need to be carefully analyzed), resulting in insufficient water flow.

Approach

The pump can be replaced by replacing the pump or disassembling the pump to clear the foreign matter in the impeller.

The evaporator is blocked or fouled

To determine if the evaporator is clogged or the evaporation tube is fouling, first remove the pump problem and make sure that the pump and inlet lines are normal.

There is a common and very obvious feature of evaporator blockage or fouling (only for medium temperature units): When the equipment is normal, the surface of the compressor will not have a lot of condensed water frosted or frozen. When you see a large amount of condensed water on the surface of the compressor, it can be judged that the evaporator is clogged.

Approach

If the evaporator is clogged or the evaporation tube is fouled, the evaporator should be disassembled, and the evaporation tube should be discharged with a high-pressure water gun or immersed in a special liquid.

note:

Some evaporators are used in chemical liquids, such as refrigerators in aluminum oxidation (anodizing) processing plants. The inside of the evaporator is a liquid containing sulfuric acid. When certain conditions are met, sulfuric acid crystallizes and blocks the evaporator. If it is a pure sulfuric acid crystal blockage, the crystal can be dissolved by circulating it in the evaporator with hot water above 50 degrees.

Others are used in electroplating plants, such as acid galvanizing. Some acid galvanizing liquids contain “potassium chloride”. When the liquid containing “potassium chloride” passes through the surface of the evaporator tube of the evaporator, the surface temperature of the evaporation tube is very low (less than the saturation temperature), which may result in “ Potassium chloride "precipitates crystals. After the accumulation of these crystals, the evaporation tube is covered with a thick layer of "potassium chloride" clothes, which causes the evaporator to lose heat exchange capacity. Slightness is manifested by a decrease in cooling capacity and a low-voltage failure in severe cases. (This is the case when the purchase is not correct)

Jiangsu Jincheng Air Conditioning Engineering Co., Ltd. is a comprehensive manufacturer specializing in the design, production, installation and commissioning of complete air conditioning equipment such as chemical fiber, textile, electronic workshop clean room and medical clean room.

Jincheng mainly produces JCZK modular air conditioning units, cooling towers, galvanized sheets and stainless steel ventilation ducts, refrigerators, polyurethane ventilation ducts and other air conditioning accessories. Jincheng Industrial Air Conditioning is favored by users because of its wide variety, wide variety, unique products and superior performance.

Jiangsu Jincheng Air Conditioning Engineering Co., Ltd. focuses on:

Industrial air conditioners, chemical fiber industrial air conditioners, chemical fiber industry refrigeration, textile industry air conditioners, clean room refrigeration, ventilation ducts, cooling towers, refrigeration machines and other air conditioning units and accessories.

If you want to know more about the product, please contact: Mr. Song 13705113637 Website: http://q045.cn/