I believe that in the use of screw chillers, more or less will encounter some faults, such as: high voltage faults, low voltage faults, low valve temperature faults, compressor overheat faults, communication faults and so on. In order to effectively solve these fault problems, we need a more comprehensive understanding of screw chillers.

As long as you have mastered the relevant knowledge of mechanical equipment and understand its performance, the problem naturally comes to an end.

Screw-type chillers are mainly used in central air-conditioning systems or large-scale industrial refrigeration because their key components are screw-type screw-type chillers.

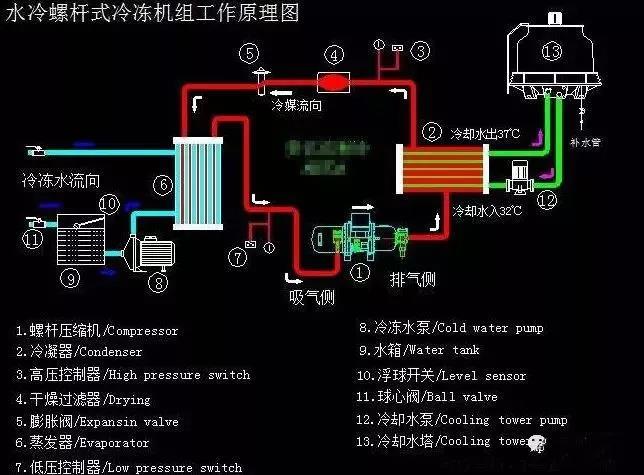

The screw chiller is a refrigerant that is in the state of the evaporator and is a gas; after being adiabatically compressed by the compressor, it becomes a high temperature and high pressure state. The compressed gas refrigerant is condensed by isostatic cooling in a condenser, and after condensation, it is changed into a liquid refrigerant, and then expanded to a low pressure through a throttle valve to become a gas-liquid mixture. The liquid refrigerant under low temperature and low pressure absorbs the heat of the cold matter in the evaporator and becomes a gaseous refrigerant again. The gaseous refrigerant re-enters the compressor through the pipeline and begins a new cycle. This is the four processes of the refrigeration cycle. It is also the main working principle of the screw chiller.

Screw chiller related refrigeration components

Condenser:

After the high-pressure superheated steam discharged from the refrigeration compressor enters the condenser, all the heat absorbed in the work (including the heat absorbed from the evaporator, the refrigeration compressor, and the pipeline) is transferred to the cooling water, and the refrigerant is overheated. The vapor recondenses into a liquid.

Depending on the cooling medium and the cooling method, the condensers can be divided into three categories:

Water-cooled condenser

Air-cooled condenser

Evaporative condenser.

Dry filter:

Prevent moisture and dirt from entering the chiller refrigeration cycle. (The source of moisture is mainly the trace amount of moisture contained in the newly added refrigerant and lubricating oil, or the moisture brought in by the air entering the system.)

If the moisture in the system is not cleaned out, when the refrigerant passes through the thermal expansion valve, the moisture will solidify into ice due to the pressure and temperature drop, which will block the passage and affect the normal operation of the refrigeration unit.

Expansion valve:

In the chiller refrigeration system, it is both a flow regulating valve and a throttle valve in the refrigeration equipment, and its temperature sensing package is wrapped at the outlet of the evaporator.

The main function is to reduce the pressure of the high-pressure normal-temperature refrigerant liquid when flowing through the thermal expansion valve, and become a low-temperature low-pressure refrigerant wet vapor, which enters the evaporator.

Evaporator:

The evaporator is a heat exchange device that relies on the evaporation of the refrigerant liquid to absorb the heat of the cooled medium.

The liquid refrigerant in the evaporator absorbs the heat in the frozen influent water and begins to evaporate. Finally, a certain temperature difference is formed between the refrigerant and the water. The liquid refrigerant is completely vaporized into a gaseous state and then sucked and compressed by the compressor (pressure and temperature). increase)

compressor:

The high temperature and low pressure gaseous refrigerant is compressed into a high temperature and high pressure gaseous refrigerant.

Circulating water tank:

Store the refrigerated circulating water, which has a float switch and a temperature detector to detect the water level and water temperature.

Chilled water pumps:

Transfer chilled water to the equipment that requires cooling.

Low pressure gauge:

Installed between the evaporator and the compressor to monitor the pressure.

High pressure gauge:

After the compressor is installed, monitor the pressure.

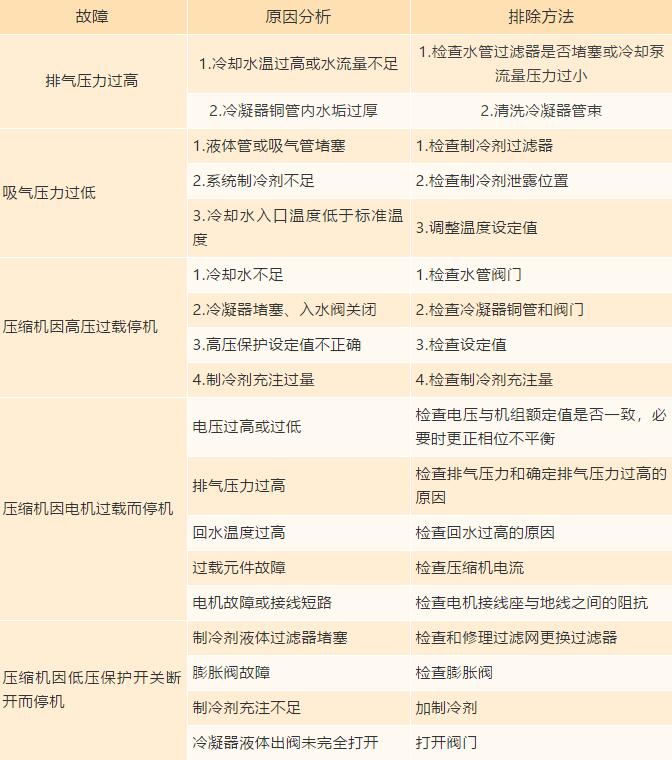

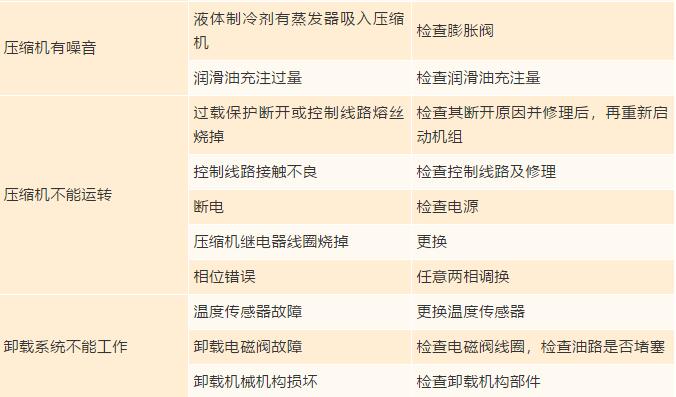

Common causes and troubleshooting of screw chillers

Some common fault problems and solutions for the screw-type chillers edited by Xiaobian are hoped to help everyone.

Jiangsu Jincheng Air Conditioning Engineering Co., Ltd. focuses on:

Industrial air conditioners, chemical fiber industrial air conditioners, chemical fiber industry refrigeration, textile industry air conditioners, clean room refrigeration, ventilation ducts, cooling towers, refrigeration machines and other air conditioning units and accessories.

If you want to know more about the product, please contact: Mr. Song 13705113637 Website: http://q045.cn/