Baidu Encyclopedia: Industrial air conditioning refers to air conditioning equipment that provides environmental temperature, humidity and cleanliness for the reliable operation of industrial products or industrial process equipment. For example, the constant temperature and humidity air conditioner used to ensure the normal operation of the electrical control indoor equipment, the high temperature environment special air conditioner used in the mobile bridge crane of the steel making workshop, the low temperature unit air conditioner used in the meat processing workshop, etc. Belongs to industrial air conditioning.

Industrial air conditioner

Household air conditioner

First of all, we need to separate the industrial air conditioner from the home central air conditioner. The purpose of the home air conditioner is to provide comfort to the indoors. The industrial air conditioner differs from the home air conditioner or the civil air conditioner in many aspects. Industrial air conditioners belong to the category of process air conditioners, and household air conditioners or civil air conditioners belong to the category of comfort air conditioners. The design of industrial air conditioners is mainly for the purpose of ensuring process requirements, and the comfort of indoor personnel is secondary.

The power of industrial air conditioners is also very large, and the power consumption is also very large. The air conditioners like our households are probably around 3000w, while the power of industrial air conditioners is as high as tens of kilowatts to several thousand kilowatts, and the time is generally all day and all. Years of operation, the service life is about 15 years. The materials required for the process are also relatively large, and are all-steel sheet metal structure plus panel electrostatic spray paint treatment, which has high anti-corrosion durability.

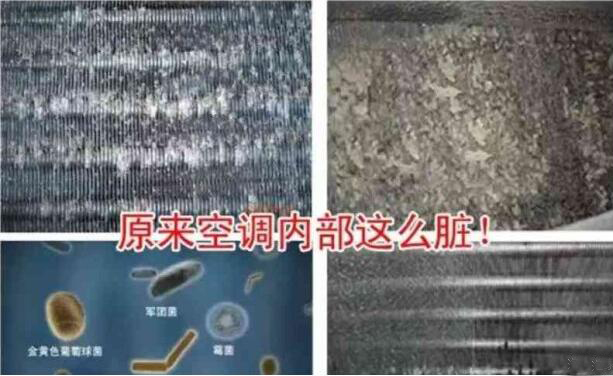

Air conditioning will not be cleaned

Air conditioning has been used for a long time, and air conditioning chilled water, cooling water system, refrigeration mainframe and fan cooling discs inevitably have scale, rust and dust problems. The inner wall of the equipment often causes the rust to fall off due to corrosion. Even the perforation, the rusted rust will block the coil and reduce the cooling effect. At the same time, the existence of corrosion greatly shortens the service life of the equipment and increases the energy consumption, resulting in an increase in operating costs. In order for the air conditioning system to operate optimally, the air conditioning system must be serviced.

Correct cleaning method for industrial air conditioners

According to the season and temperature, the industrial central air conditioner should be used reasonably. It should be cleaned and repaired regularly. If it is not used for a long time, it should be closed. Remember: the bottom basin should be cleaned once a day, so that the wind is more clean.

Unwashed air conditioner and cleaned air conditioner

1. Industrial central air conditioning physical cleaning

The common physical cleaning method is to use a main gun, that is, through tightening air or manually, a tool such as a punch, a rubber stopper, a nylon brush or a round steel is passed through a heat exchanger tube to remove deposits or infarcts in the tube. Open the end cap of the main machine and use a gun to pass the guns one by one to clean the bio-mud and rust of the pipe wall. After the gun is finished, rinse it with high-pressure water. Then completely remove all the rust and scale on the side of the water chamber and the inner wall of the end cover, and brush the anti-rust paint twice to play the role of derusting, rust prevention, descaling and anti-scaling.

2, industrial central air conditioning chemical cleaning

A type of cleaning method in which the deposit in the equipment to be cleaned is dissolved, loosened, scattered or peeled off by the action of a chemical agent. Commonly used chemical cleaning methods include pickling, caustic washing, complexing agent cleaning, sterilization cleaning, and the like. Chemical cleaning is commonly used to remove hard dirt and bends in the equipment, pipes, and deposits at the joints. Adopting a professional single-stage cleaning method, using organic acid plus complexing agent and high-efficiency corrosion inhibitor, the corrosion of copper tube is ten times lower than that of inorganic acid, and it can quickly descale on the base of effective maintenance equipment. Rust removal. After the cleaning is completed, the pretreatment of the copper tube is stopped, which can greatly delay the corrosion rate of the equipment.

Correct maintenance method for industrial air conditioners

In order to extend the service life of air conditioners, special teams should be set up to include management activities such as maintenance and storage; do not frequently turn off and turn on the air conditioner, and do not frequently change the working state of the air conditioner.

1. Check whether the electrical circuit is wrong, and test the insulation resistance of the electric circuit, compressor and fan motor respectively. The insulation resistance is greater than 2M ohms. Whether the terminal block and the crimping line are loose, and the power cord is aging.

2. Check whether the system is magnetically bumped or leaky, and do an experiment to verify the leak tightness to ensure that the system pressure is normal.

3. Check if the reversing valve has a string of gas and a leak point, and make comprehensive maintenance.

4. Check whether the external three-way valve leaks and replace it regularly.

5. Whether the filter has a blockage and is operating normally.

6. The operation of the compressor fan, whether there is any abnormality, whether the vibration and noise are normal.

7, drainage system, to ensure that the condensate can be smoothly discharged.

8. Check the aged bandage to re-encapsulate it.

Proper cleaning and maintenance of the air conditioner can prolong the service life of the equipment, reduce the occurrence of accidents, and keep the system running for a long time.

Whether it is work or life, health is often placed first. Every summer and winter, air conditioning is an intimate partner of many indoor life and workers. If you don't understand it, this intimate partner will often play temper and even hurt the owner's body; that is, after the air conditioner is installed, Representing once and for all, correctly mastering the use and maintenance methods of air conditioners can not only reduce the cost of air conditioning, improve the use of air conditioners, but also make people and air conditioners "longevity".

Jiangsu Jincheng Air Conditioning Co., Ltd. is a comprehensive manufacturer specializing in the design, production, installation and commissioning of complete sets of air conditioning equipment for chemical fiber, textile, subway engineering, electronic workshop clean room, electric power, tobacco, civil air defense engineering and medical clean room. The products sell well in dozens of provinces and cities across the country, and are exported to overseas. Jincheng air-conditioning is your trustworthy brand!