The light snow has passed, and the cold air in winter is coming soon. In the cold winter, in the subzero temperature, everything is shivering in the cold, only the air conditioning is not afraid of the cold, bringing us warmth!

However, the central air-conditioning is by no means not afraid of freezing, and the friendship is reminded: Please don't forget to do the anti-freezing measures for the hard-working air conditioner.

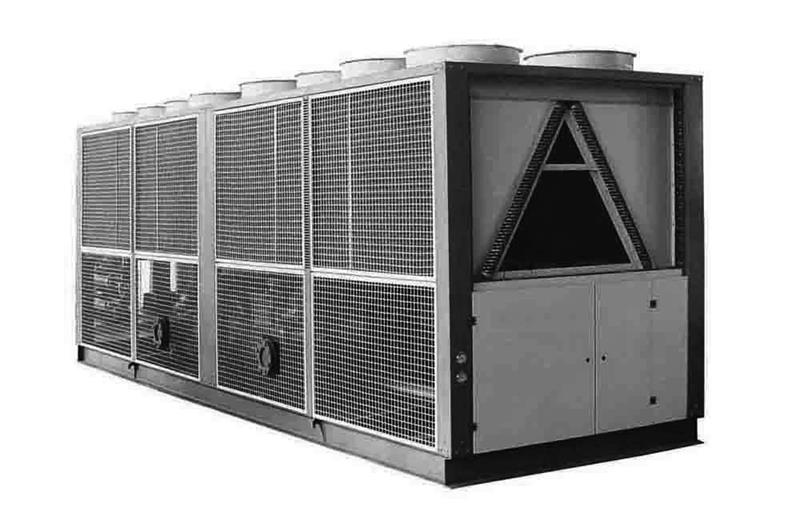

Antifreeze method for air-cooled chiller

For air-cooled chillers, because of the water-cooling heat dissipation, there is no water-cooling system for water-cooled chillers. Only the fans need to be anti-freeze in the heat-dissipating part of the air-cooling machine. The focus should be placed on the lubricating oil of the fan. If you run continuously, you don't have to worry about the antifreeze of the lubricant. If the chiller is used intermittently or not used for a long time, you should pay attention to antifreeze.

If it is not used for a long time, the air-cooled machine should be cleaned and coated with protective oil. It is best to be waterproof to prevent frostbite in the air-cooled machine caused by cold air in winter.

For intermittent use, the fan oil should be scraped off when it is stopped, and then apply an appropriate amount of lubricant when using. In the case of normal operation of the air-cooled chiller, sufficient water flow and water pressure are ensured, and the problem that the cooling water is frozen is not substantially caused.

Jincheng reminds you that you should pay special attention to the following two points when using air-cooled module units in winter.

(1) Resolutely put an end to power outage during use, especially in the winter, the host has antifreeze function in general, even in the state of shutdown, the air conditioner host will freeze in winter, but if the power is off, this function also It will not work. Of course, we must ensure that the main engine and the pump are automatically linked.

(2) If there are other heating measures in winter or the equipment does not require the host to participate in heating, then it is recommended that you close the water valve and discharge the heat exchanger. Of course, due to design or other reasons, the water release will not be very thorough, so In very cold areas, if you have the conditions, you can let them drink some wine, that is, you should drink it for you to drink, and there will be no worries for the coming year.

Antifreeze method for water-cooled chiller

Unlike water-cooled chillers and air-cooled chillers, the cooling and cooling components of water-cooled chillers are water circulation systems rather than fan systems, so the anti-freezing task is even more difficult. Antifreeze work is carried out even during normal operation.

Start with the water cooling system to check and prevent the cooling and freezing. Generally speaking, in the winter, the water-cooled chiller is recommended. It is recommended to add antifreeze to the cooling water, but it is necessary to clarify the concentration of the antifreeze in the water, the ratio of the antifreeze to the cooling water. If it is added less, it will not have the antifreeze effect. If it is added, it will cause corrosion to water cooling systems, such as pipes and seasonings, water towers and so on.

In addition to the water cooling system, you should start with the refrigerant. When the refrigerant is too cold, the problem of trait changes may occur. If you do not use a water-cooled chiller for a short time in winter, you should always warm it up. Before the official use, the water pump, cooling tower, and compressor should be opened.

Jincheng reminds you that water-cooled chillers are more difficult to freeze because of the arduous task of anti-freezing.

Host antifreeze

Close the main condenser and evaporator inlet and outlet valves, open the drain valve and the vent valve, and then use compressed air to blow off the remaining water.

Antifreeze of water pump

The refrigerant pump inlet and outlet valves are closed, the water pump drain valve and the vent valve are opened, and the water is drained. Open the lowest point of the cooling water system, release the cooling water, and open the water pump drain valve. After the system water is drained, in order to prevent rainwater from entering through the cooling tower, close the cooling tower water outlet main valve and open the cooling tower water collection drain valve. So that the rainwater is drained from the drain valve in time.

Antifreeze of cooling tower water supply pipe

In general, the cooling tower water supply pipe is exposed to the outside, and most of the designers use the insulation method to prevent freezing. However, in actual use, even if the heat preservation is performed, the freezing phenomenon often occurs.

In order to solve this problem, when the cooling tower water supply pipe is taken out from the room, a valve is added, and a drain valve is added at the lowest point of the water supply pipe. When the winter comes, turn off the valve in the room and open the lowest point drain valve to drain the water in the outdoor tube so that the pipe does not need to be insulated and will not be cracked.

Antifreeze of expansion tank

The expansion tank is generally located in the equipment room of the roof or the top floor. Although the expansion tank has heat preservation and a circulation pipe, in actual use, the circulation pipe can really have a small circulation effect, that is, there is an expansion tank in the winter. The water is in a low temperature environment for a long time. Although it is kept warm, it will still be frozen. If the expansion tank is frozen, it will not be expanded. When the temperature in the system rises, the pressure will increase.

In order to solve this problem, a DN20 interface can be set in the air conditioning water supply main pipe during construction, and a valve is properly opened to ensure that the water in the water tank is circulated. If the air conditioner is not used at night, the valve can be fully opened before the pump stops, so that the water temperature in the expansion tank rises, and the expansion tank does not freeze for a long time after the pump is stopped.